Measures and results

HOW IT WORKS

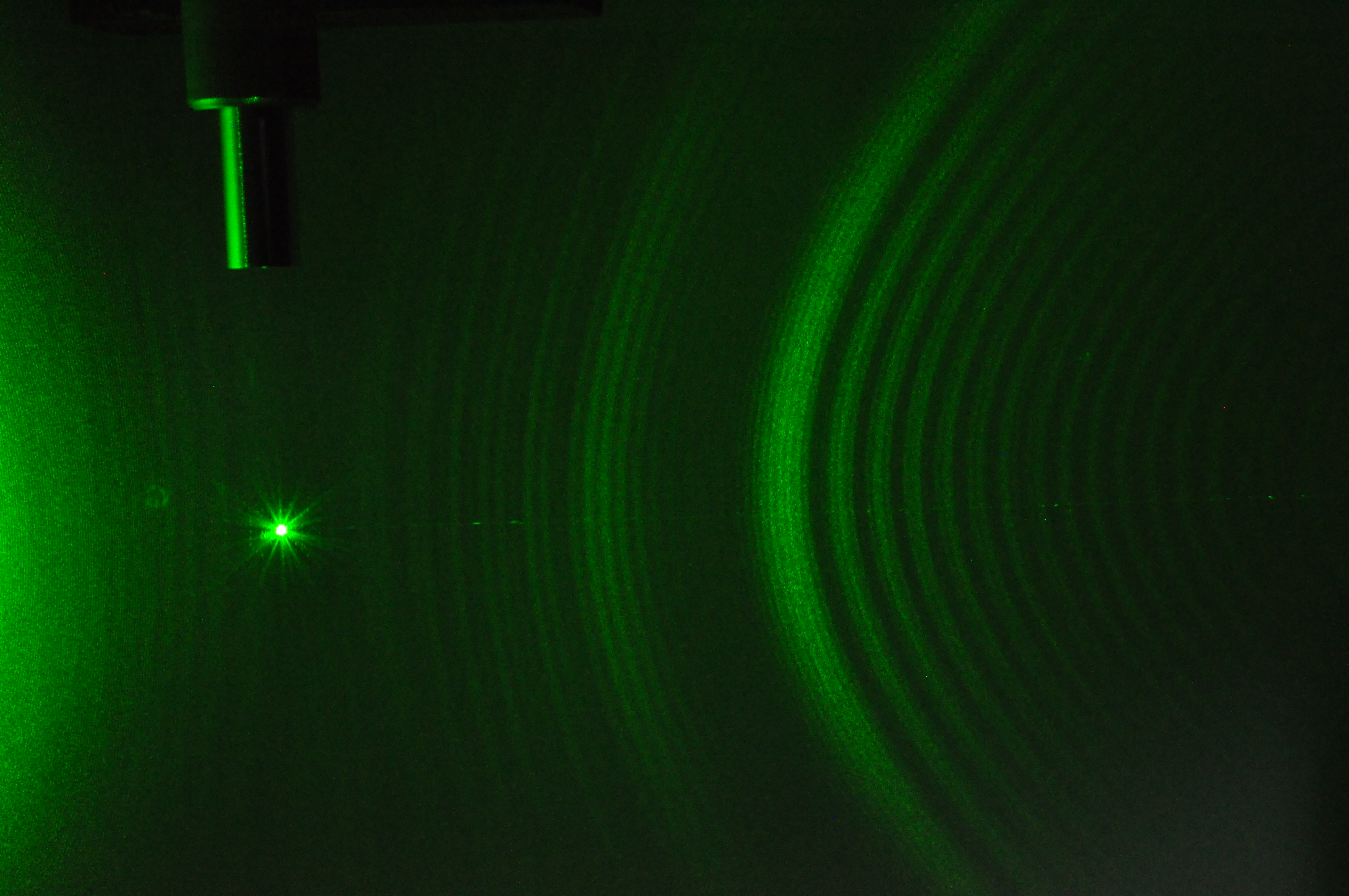

RainbowVision’s instruments are based on the analysis of the light scattered around rainbow angle called Global Rainbow Technique (GRT). The rainbow position gives the information on droplet average refractive index therefore average droplet temperature. While, the rainbow shape codes the information on size distribution.

Our devices consist in a unique assembly combining an emission unit and detection unit. The emitting part is based on laser (wavelength 532 nm or 640 nm, with an adjustable power between 1 and 200 mW). The light scattered by particle from the measurement volume (typically 1mm³) is recorded by CCD camera. The analysis of recoded global rainbow images by a dedicated proprietary software allows to extract from each image, in real time, the average temperature of the drops and the associated size distribution. Our devices can be controlled remotely and allow you to work up to 3 hours without external power.

Depending on the size of the installation to be characterized, the RainbowVision’s device is installed:

- Outside the test medium: Accordingly the measurements are carried out through an optical window (GRT-XL Model),

- Inside the installation: In this case GRT-Mini Model can work directly in the spray.

Example of application in combustion

Our technology is used to study the droplet thermal behavior during diphasic combustion. The next figure represents, at the top, a V-shaped flame. The blue color is the average location of the flame front obtained by meansing 200 IMAGES of OH fluorescence. The green color represents the location of N-Heptane drops of an average size of 20 microns, obtained by Mie scattering.

At the bottom are the droplets temperature measurements obtained by GRT. The distance between two measuring points is in the order of 2 mm. The increase in the temperature of the drops according to the distance to the flame front is clearly highlighted and quantified.

Example of application to icing

RainbowVision is a partner in the H2020 ICE-GENESIS program, led by AIRBUS. As partner of this european program, our mission is to provide devices to measure in situ the temperature of water drops in Icing Wind Tunnels (IWT). Depending on the characteristics of the wind tunnels, two different configurations are provided:

- For small test section IWT, the measurements can be made from the outside through an optical window by using GRT-XL model,

- For large test section IWT, the GRT-Mini device is installed inside the wind tunnel, in direct contact with the flow, under the rain with strong negative temperatures (up to -40oC) and hig flow speeds (up to 100 km/h).

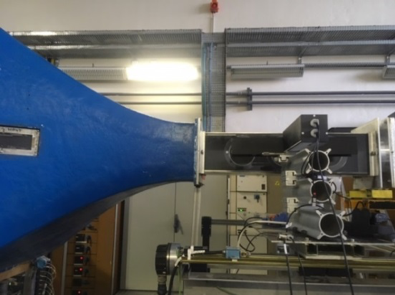

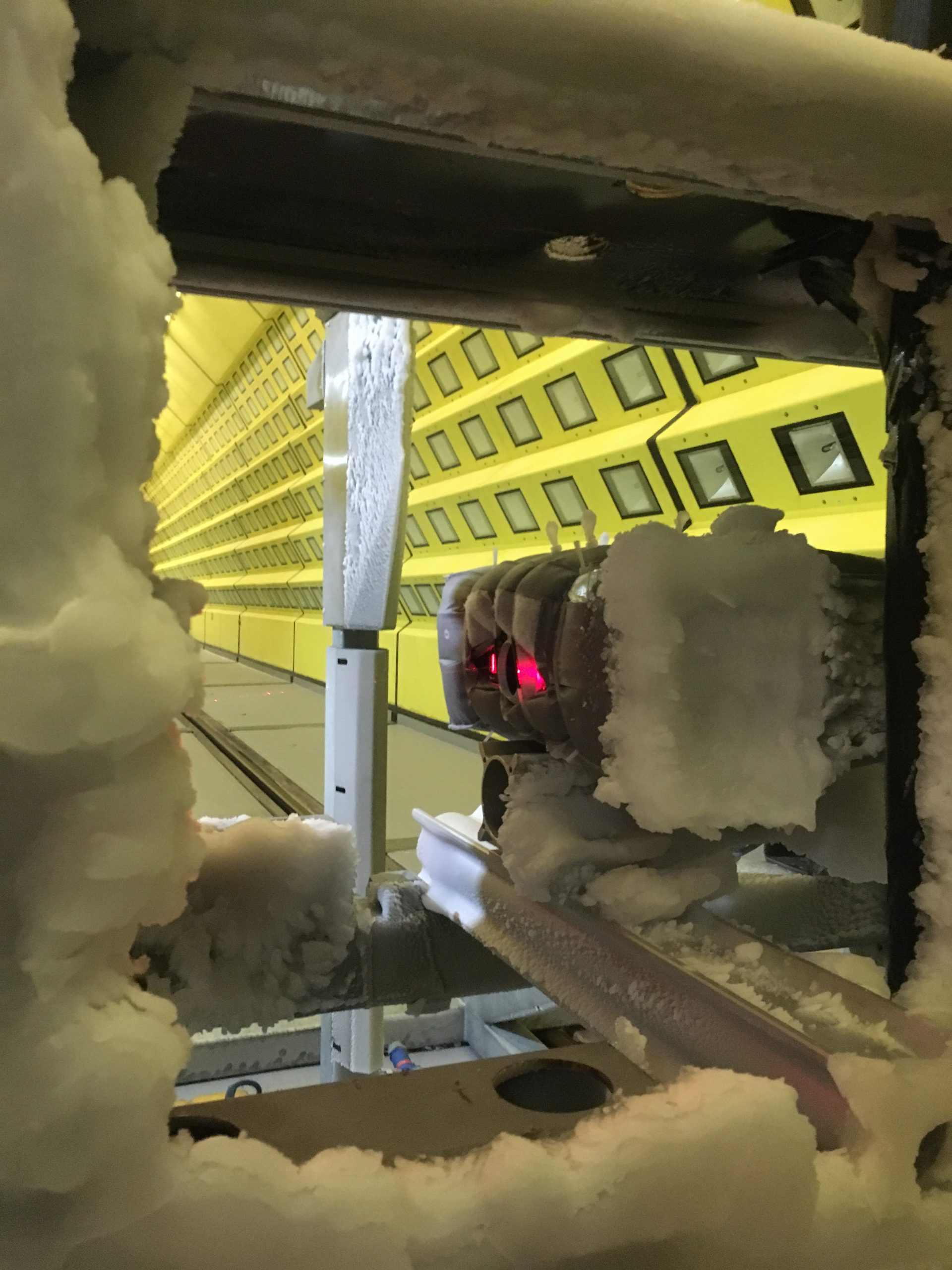

The following figure illustrates these two test configurations.

On the left, the installation of a GRT-XL on the DGA IWT (20 x 20 cm section, flow speed up to 250 m/s or about 900 km/h)

On the right, the installation of a GRT-Mini in the RTA IWT in Vienna (Austria). The test section is 4.5 m x 4.5 m for a length of 100 m. The air speed can reach 100 km/h.

The objective of these studies is to master the icing by measuring the temperature and size distribution of the droplets at an impact point. The droplets temperature depends on IWT working condition as the air flow speed, air temperature, the droplet size and etc,. Droplet temperature is a key parameter to validate numerical simulation codes and physical de-icing systems.

The figure below is an example of a such measurement showing the evolution of water drop temperature when the air flow velocity is gradually increased from 150 to 200 m/s [3].

An example of how the droplets temperature in the wind tunnel changes according to the air flow speed. As the residence time depends on the air flow speed, higher the air flow speed is, highrer the droplets temperature is! the droplets do not have time to be in thermal equilibrium with the cold air flow.

Example of application in heterogeneous chemistry: capture of CO₂ by drops of MEA

GRT devices measure the drop refraction index. They are also perfectly suited to quantify the degree of progress of a chemical reaction between the drops of a liquid and a gas phase. For example, for the study of the local efficiency of capturing CO2 gassed by drops of Monoethanolamine (MEA).

Indeed, the chemical reaction causes a change in the refraction index. The measurement of this refraction index is therefore a measure of the state of the chemical reaction. It is then possible to optimize a CO2-capture spray column based on the size of the drops, their concentration, their speed, the geometry of the column. An example of such an application is available in the following reference [4].

[4] M. Ouboukhlik, G. Godard, S. Saengkaew, M.C. Fournier-Salaun, L. Estel et G. Grehan, Mass transfer evolution in a reactive spray during Carbon dioxide capture, Chemical Engineering Technology, vol. 38, n° 7, 1154-1164, 2015

Ouboukhlik, S. Saengkaew, M.C. Fournier-Salaun, L. Estel et G. Grehan, Local measurement of mass transfer in a reactive spray for CO2 capture, The Canadian journal of chemical engineering, vol 93, 2, 419-426, 2015.